Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

Ever wonder how cars, bikes, roller skates and even glass roadways move so easily? And it’s all thanks to a small yet mighty little thing known as a joint cross bearing wheel. These tiny miracles do a lot to make objects roll smoothly and easily. We would be bouncing and knocking our heads together whenever we go for a spin if we didn’t have them

Quality is the key when selecting a bearing wheel. A good set of bearing wheels, such as those from Fo Bearings, can make a big difference to how your wheels perform. They help decrease friction, so your wheels can roll more easily and not get stuck. That means you’re able to go faster and further with less effort, whether you’re riding your bicycle around the block or racing down a skateboard ramp.

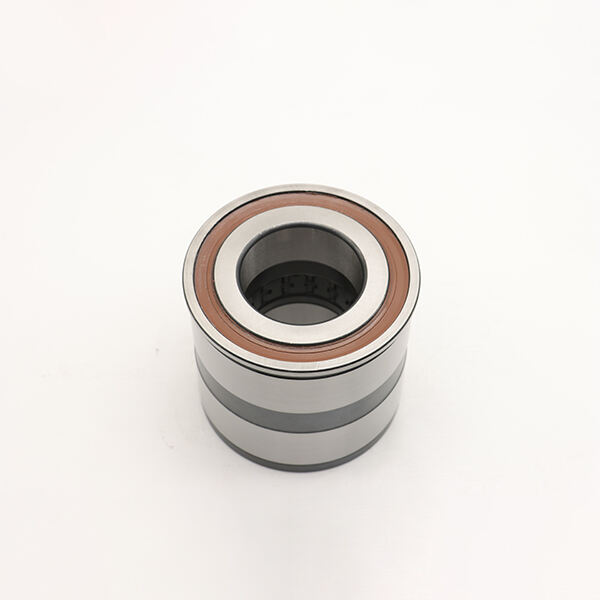

So how do bearing wheels work their magic? Small balls or rollers inside each cross joint bearing wheel are designed to minimize friction while the wheel spins. These balls or rollers are nestled between two rings, also called the inner and outer races, that assist in containing everything. When you turn the wheel, these balls (or rollers) roll along with it, allowing the wheel to spin smoothly and freely. It's as if you would have little people inside your wheel, pulling the right strings, making everything work seamlessly

There is definitely no “one-size-fits-all” when it comes to bearing wheels. Some are designed for heavier-duty uses, like industrial equipment, while others are great for lighter applications, including skateboards or scooters. Fo Bearings has a variety of bearing wheels to meet different needs, so if you want something that’s tough and durable or slim and quick, you’ll able to find the perfect wheel for you.

How To Take Care of and Keep Your Bearing Wheel Safe.

Proper maintenance is important to keep your skates bearings wheels rolling smooth. Below are some simple strategies to help you maintain the life of your bearing truck wheels:

Inspect your bearings for rust, dents or any other damage on regular basis. If you hear something abnormal, then make sure to replace the bearing before it causes anymore damage.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.