Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

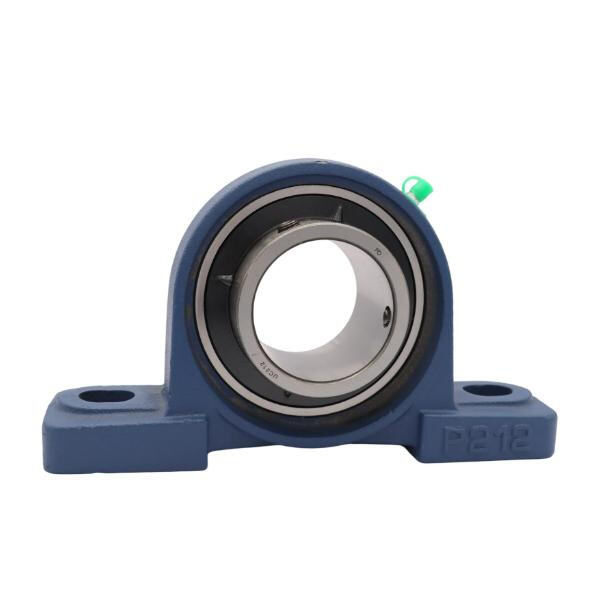

2 Split bearing housing is an important type of housing which helps to replace the bearings faster in machines. The casing comprises a first member and a second member, which is split. This allows you to remove the bearings without removing the entire housing. This significantly reduce the time and energy needed for a repair and/or maintaining equipment.

Split bearing housing has one great advantage and that is it makes maintenance of machines convenient. Because the housing has two parts, the bearings are easier to reach and can be replaced as needed. This helps minimize downtime and maintain healthy machines.

Split bearing housing is the solution to bring a longer life for equipment. This type of housing can help change bearing to be mounted in a certain place. The latter action is to prevent other portions of the apparatus from being damagedb. It can make the equipment work better and longer.

The split bearing housing is suitable and can be employed in a wide array of places, so it can be a good choice for a multitude of jobs. You can find it in huge machines like construction equipment and mining machines, but you can also see it in smaller ones like pumps and conveyors. The versatility of split bearing housing has led to its wide spread usage across all types of machinery.

If you are in search of split bearing housing, there are several bit important things to keep in mind that will help you to choose a product that will suit your needs. Look for items like durability, ease of installation and if it fits your machine. When you select such a split bearing housing, your machines are performing in an optimal manner.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.