Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

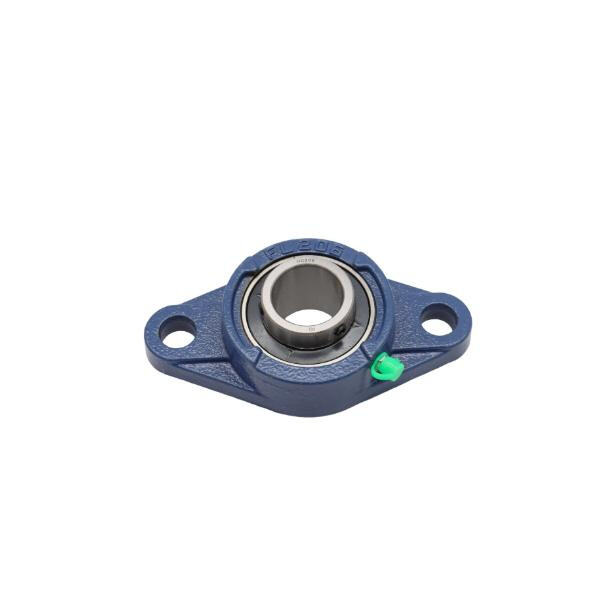

Equiped with roller bearings or spherical bearings instead of ball bearings, split housing bearings (sounds important, doesn’t it?) are designed to help machines run smoothly. The special bearings are formed in two parts and convenient for installation and maintenance. The split design enables them to better accommodate heavy loads and vibrations than regular bearings. At Fo Bearings, we understand the working principle, structure, and significance of split housing bearings for machines.

Tapered and split housing bearings are the heroes of industrial because they are extremely versatile and can be used in many different machines and tools. Split housing bearings are used in applications where the bearing is to support axially moving parts: in industrial plants, power plants and vehicles. They’re efficient, after all: Easily replaced or fixed without disassembling the entire machine. That means machines can work more and spend less time sitting idle.

TLC for split housing bearings Split housing bearings need love, too. Frequent lubrication can diminish weat and friction on the bearings. And, pay attention for any signs of damage or misalignment, as this can be detrimental to the function of the bearings.

Machines that are heavy-duty require powerful and durable bearings to perform heavy tasks. These machines need split housing bearings in order to deal with large loads and demanding conditions. Their two-part design eases maintenance and replacement, saving money in heavy-use environments where downtime can be costly. Heavy machinery rely on FOBearings to bring you the best in quality split housing bearings.

Machines run more smoothly and last longer with the right bearings. The split housing bearings are critical to better performance of the apparatus on account of the ease in which they can tolerate high speeds, heavy loads and the like. By minimizing friction and wear, these bearings help machines and equipment run more efficiently and last longer. Selecting top-notch split housing bearings from Fo Bearings will keep your machines sublimely silent over the years.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.