Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

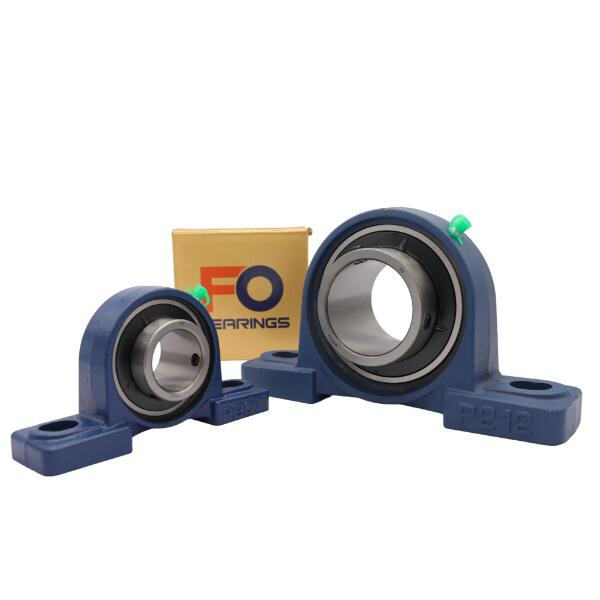

Spherical bearing housing, which is an important part of the machines from the factory. It flexes to hold things in place and helps them move in all sorts of directions. The bearing block housing encases the spherical bearing to keep it safe and secure, and that’s important for the machine to function as it should.

There are many advantages to the use of spherical bearing housings in machines. First, it cuts down on friction, and that cuts down on the amount of wear and tear. This is one of the things that adds longevity to the bearing and machine. Plus, the housing can adapt if parts aren’t precisely aligned, key for machines that move a lot. Altogether, machines will tend to work better and last longer with such Fo Bearings spherical bearing housing.

Proper installation and maintenance of the spherical bearing housing is absolutely key to getting the best performance out of it. To install it, just bolt it down to the machine, line it up with the bearing, and you're good to go. Taking regular care, such as adding lubricant and looking for damage, can help keep the housing flange working well.

There are a few key considerations to take into account when selecting a Fo Bearings spherical bearing housing for your machine: First, select a housing that is the proper size and type for your bearing. Also consider the load anxiety of the machine and the environment where it will work. You can improve your machine’s performance and reliability by selecting the proper housing.

Spherical bearing housing is very useful for machines of heavy duty as it can endure heavy loads and harsh working conditions. The housing delivers stability and support, reducing the risk of damage and downtime. Embracing Fo Bearings Spherical split bearing housing is more comfortable to move it is equipped to turn it is heavy-duty machine to provide longevity any make of the grinding machines. In general, the type of housing described can enhance the efficiency and ruggedness of the machinery.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.