Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

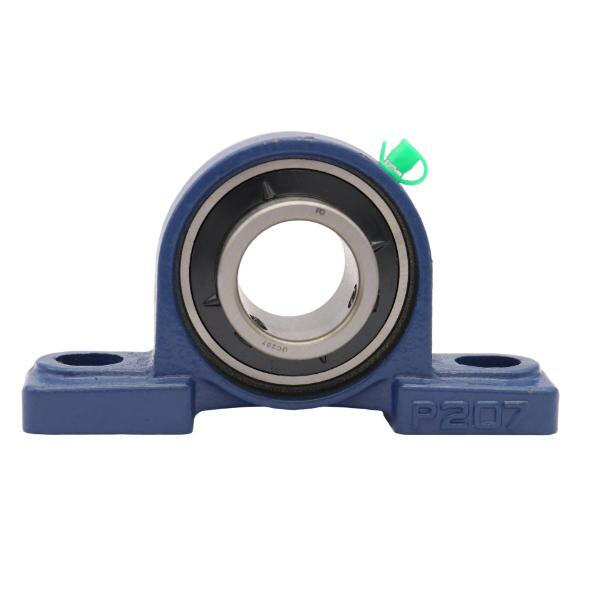

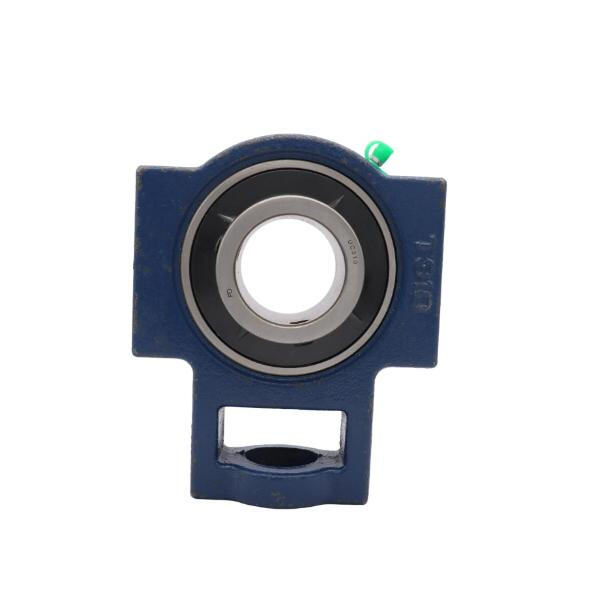

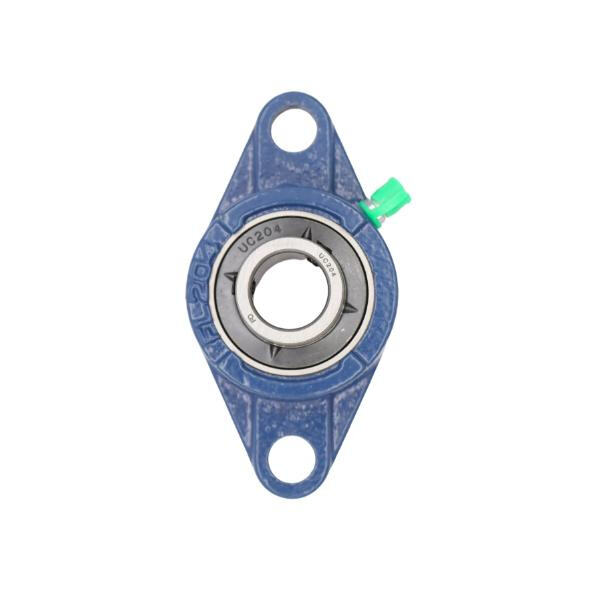

Ball bearing housings are used in a wide variety of machinery. They are instrumental in minimizing friction and permitting smooth movement. As the top leading ball bearing housings supplier, Fo bearing cross joint is here to help you recognize the significance of this part and to perform the necessary maintenance on them for financial savings.

Ball bearing housings are an important part of various types of machinery as they support and protect the ball bearing that they contain. These housing also support the bearings as to not allow them to be destroyed by over pressure or side impact. With the loss of a strong housing, ball bearings may not be effective, causing machine failure and expensive repairs. With ball bearing housings from Fo Bearings, you can be sure your machinery is running smoothly and with reduced vibrations.

Good maintenance is an important aspect in maintaining the life of ball bearing housing. Regular inspections and lubrication can avoid the wear and tear and keep housings function well. The house should be cleaned every so often, and the damaged or bare parts should be replaced in time. By performing these basic maintenance tasks, you may be able to eliminate the down time and the expense of unnecessary repairs and save yourself a few extra dollars down the road.

Friction is one of the problems which the machinery often have, and it affects the performance and life of the moving parts. Ball bearing cartridges were specified to reduce friction by providing a smooth surface for the ball bearings to roll against. This reduces the heat and wear enabling the equipment to work more efficiently. With the ideal ball bearing housing for your applications at For bearing truck, you can help minimize friction in your equipment and enhance efficiency.

If you’re considering a ball bearing housing that’s suitable for your machinery, you need to take a few things into consideration. The first thing you will want to do is figure out the size and type of ball bearings your equipment needs. You should also take the dirver's operating environment, including temperature and load capacity, into consideration to make sure the housing can handle the rigors of your machine. And by selecting a quality supplier, going with Fo Bearings make all sorts of housings that can lead you right to the perfect one for your needs, which will keep your machinery working like it should.

Ball bearing housings are generally constructed from a number of different materials including steel, aluminum, and plastic. However, each material has its distinctive properties and advantages, and is appropriate for given machinery in specific operating conditions. The steel housings are incredibly durable and strong; perfect for those high impact spots and heavy duty uses. Aluminum housings are lightweight and corrosion resistant to withstand use in demanding applications. Plastic housing is cost-effective and easy to install in light duty applications. When you know the various types of materials used for bearing roller cylindrical & ball bearing housing builds, you can select the correct choice for your equipment and get a longer lasting service life.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.