Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

Shaft bearing housing is one of the machines are essential for the operation of a good. Understanding the importance of joint cross bearing is crucial if you want to ensure everything runs like a well-oiled engine. What is shaft bearing housing, and why does it matter?

One such piece is the shaft bearing housing. It prevents the shaft from sticking. This component serves to reduce friction and wear between components that move, something that can prolong the life of the machine. The equipment can fail or break down without shaft bearing housing.

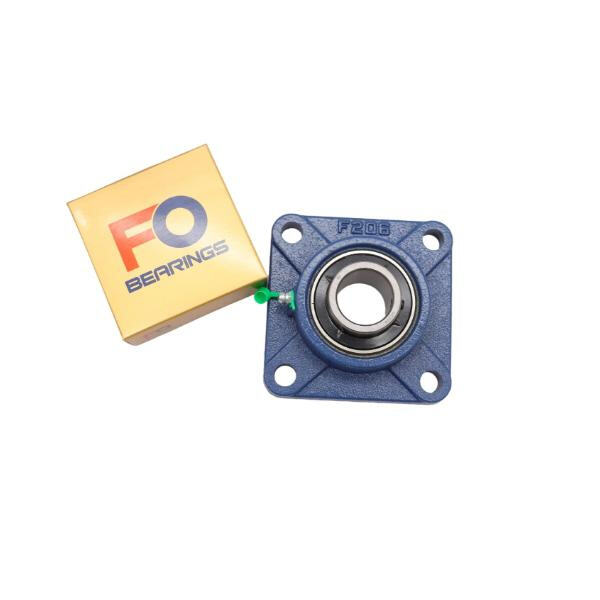

There are various types of axial cylindrical roller bearing, which are manufactured for the various machines and conditions. You’ll see many types of mounted bearings, including pillow block bearings, flange bearings, and take-up bearings. They can accomodate a range of shaft sizes and weights, so pick one that’s right for your machine.

It is essential to maintain the shaft bearing housing regularly if you want your machine to function properly. This could involve greasing up the bearings, inspecting for wear and tear, or replacing any pieces that have snapped. By maintaining the shaft bearing housing, you can prevent costly repairs and keep your machine running smoothly.

Shaft bearing housing can occasionally have some problems such as being too noisy, shaking or being too hot. They can signal an issue with the bearings or the housing itself. Making sure to inspect the bearing housing on the shaft and to remedy any problems will ensure that no further damage is caused, thus allowing your machine to continue to run smoothly.

Both the platform and shaft bearing housing are getting better as technology allows. Newer shaft bearing housing may be sturdier, well-functioning, and enable machines to run better. NEW SHAFT BEARING HOUSING upgrades will assist in better performance of your machine and reduce the risk of breaking down.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.