Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

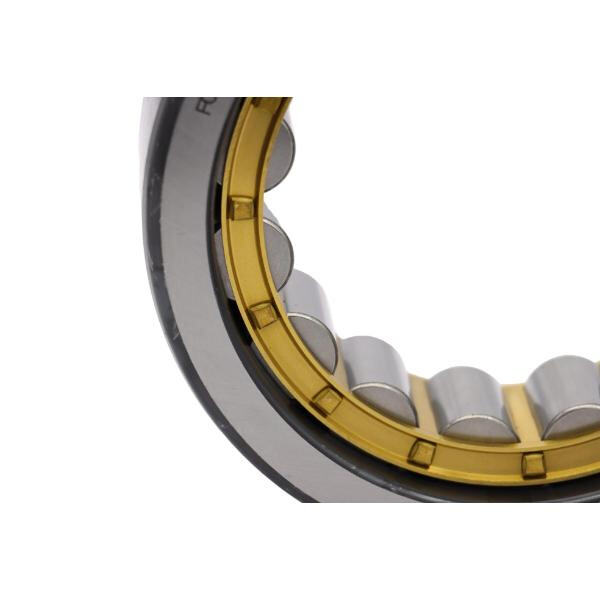

Taper roller bearings of cylindrical type, such as the ones produced by Fo Bearings, are assembly components that help to facilitate the operation of machines. Think of a big wheel turning. Inside that wheel are small rollers that help it to turn easily. Cylindrical taper roller bearings are perfect for this application!

Cylindrical taper roller bearings They are cylindrical in shape, in the form of two truncated cones. They have two rings, one inside the other, and a few cages and rolling elements. They’re shaped pointy to facilitate spreading the weight out, which makes them strong and long-lasting. When machinery is in motion, these bearings also minimize friction, so that everything functions optimally.

Fo Bearings’ tapered cylindrical roller bearings are not just really good at what they do, but they’re also affordable. They can carry big loads, and go fast, without falling apart. That’s a machine that machines that use these bearings can remain in good working condition for a long time. You can trust those machines with the help of quality bearings from Fo Bearings.

Technology never stops advancing, and neither do clyindrical taper roller bearings. Fo Bearings is always evolving and looking into ways to improve their bearings. They are made in more advanced materials and ways, which makes them stronger and more able. These new innovations enable machines to work more efficiently and last longer, saving businesses time and money.

There are many advantages to using Fo Bearings' light/medium duty and custom-designed joint cross bearings in construction, mining and other industrial applications. They can bear heavy loads and harsh conditions. This makes it cheaper to repair things and to keep machines running longer before replacing them. With Fo Bearings superior bearings, business can perform better.

Once you pick out cylindrical taper roller bearings, this is for you to select the appropriate size as well as the sort for your machine. Fo Bearings has a variety of options and definitely give their experts a call to see what is best for you. If you get the right ones, he says, obey the install instructions from Fo Bearings, and your machines will run like a top.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.