Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

Ever wonder how stuff moves so easily? You may also wants to consider single row roller bearings. These little pieces make machines work better. Now, let’s dive into what a Hub Bearings is, why it matters, and how they work.

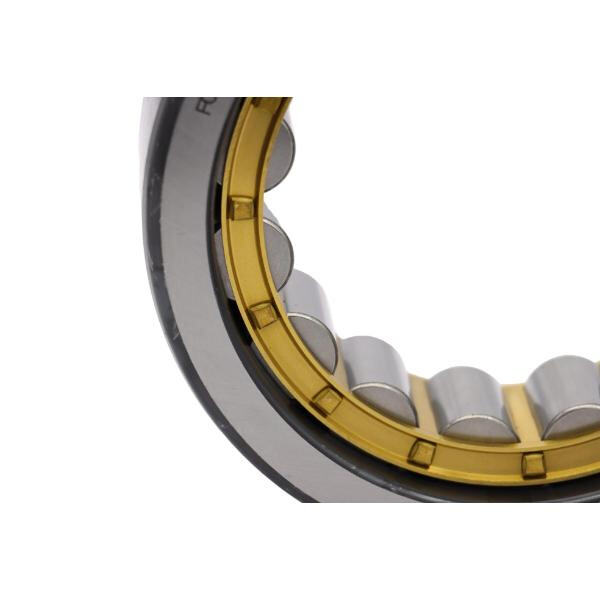

Roller bearings, of which we will consider only those with a single row of rollers, are the small round components that are used to decrease the pressure of large machinery and make it work smoothly. They are largely made from steel and contain small cylinders known as rollers. These are rollers that distribute the weight of a machine’s moving parts over a larger area, so movement doesn’t get stuck.

There are a number of good reasons why Fo Bearings single row roller bearings are so commonly used in machines. One of the biggest perks is that they can accommodate bulky items without degenerating quickly. The rollers inside the bearings reduce stress by distributing weight more evenly, preventing any one area from being under excessive pressure. First, Truck Bearings are convenient to install and do not require much maintenance, so industries made a good decision to use them.

Single row roller bearings are used in most applications. You can also find them in cars, trucks, trains and airplanes — there, they lubricate the wheels and axles, so they move easily. They also appear in industrial machines, including conveyor belts, cranes and pumps, where they help reduce friction and enhance performance. All things considered, these Clutch Bearings have a great significance in maintaining machines in prime condition and preventing problems from occurring.

To help us understand how Fo Bearings single row roller bearings work it’s useful to try and understand their design. These Hydraulic Clutch Bearings have a homely appearance, with a steel outer ring, an inner ring and rows of rollers in the middle. The rollers roll smoothly in the bearing, which cools the mechanism by minimizing friction and allows the parts of the machine to move freely. Single row roller bearings essentially act as a cushion for two moving parts, preventing them from grinding against each other and wearing down.

Consider a few things while selecting a Fo Bearings single row roller bearing for your machine. First, consider the size and weight of the moving parts, and confirm that the bearing can accommodate them. But next, consider how fast the machine is going, because some bearings are specifically for high-speed use. Finally, opt for a bearing that’s constructed from sturdy materials (examples include stainless steel) to ensure that it stands the test of time.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.