Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

Selecting the proper pillow block bearing makes certain that your equipment performs at the level you need. The pillow bearings that help your machines work more efficiently don’t have to wear out fast.

While considering a pillow block bearing housing for your machine, ensure that it can carry the weight and motion of that machine. If you do choose a pillow with a certain bearing that is too small or doesn’t support the machine’s weight enough, it can cause the pillow to break; and the machine would not be able to operate any more if that were to happen. Fo Bearings have a wide variety of pillow bearings that might work on a range of different machines so check with them to see which on will fit yours.

Pillow block bearings contribute to the overall efficiency of the machine. They serve to minimize friction and to ensure that all parts of the machine are moving smoothly. With good joint cross bearings, your machine will do the work, and you can enjoy it for that much longer. Not only that, but when you choose pillow bearings for your machine from Fo Bearings, you can have confidence that your machine will have great performance.

To ensure your pillow bearings last for more than a little while, you have to look after them. This entails that you maintain them- checking as to whether they require lubrication or need cleaning. If you notice any wear or damage get the pillow bearing replaced in time. Fo Bearings can tell you more on how to maintain your pillow bearings and keep your equipment in papge running condition.

Pillow block bearings may be worth consideringif you are still operatingmachines with ancient bearings. These bearings can withstand heavy loads and enable your machines to work more stably. But some improvement from Pillow Block Bearings from fotebearings would be able to let your machines running better and insure less problems.

Pillow bearings can experience several issues as time goes on. One major problem is a lack of lubrication, which can cause the bearings to fail faster. To prevent this, inspect your pillow bearings and apply some lubrication. If you hear unusual noises, or a notice any strange movements in your machine, that could be a sign that the pillow bearings should be replaced. Fo Bearings if you need your pillow bearings problems can all be solved.

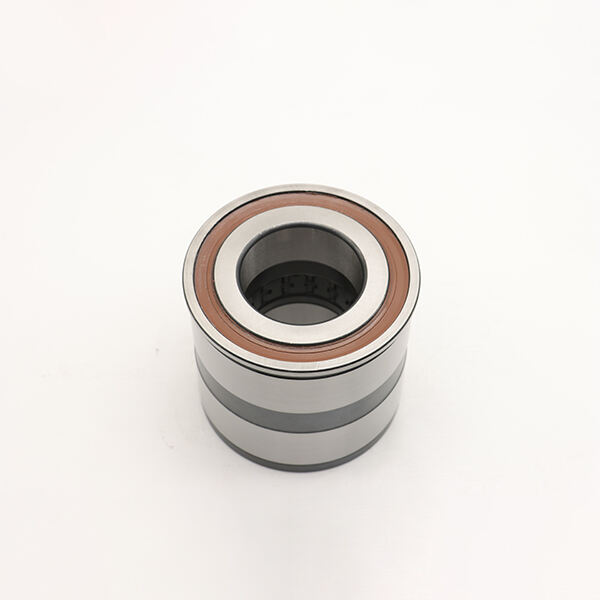

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.