Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

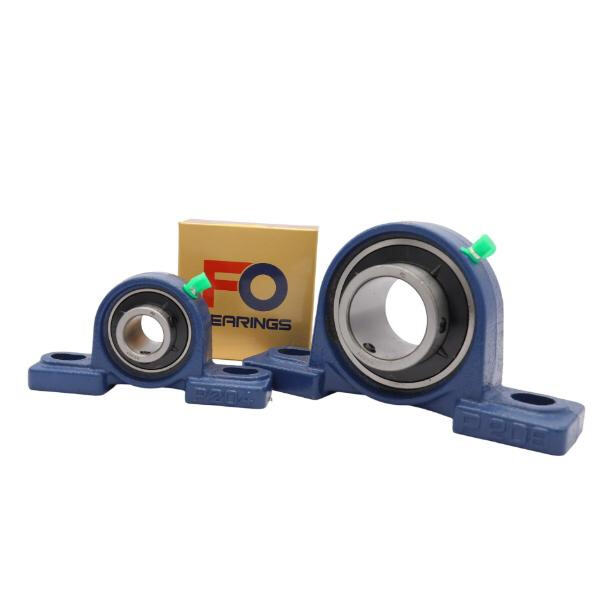

Roller Bearing Housing As One Critical Part to Work Machines Well Roller bearing house is an important part in machinery. Given that we use these parts of the body all day long, it is important to keep them in good shape so we can use them for a long time. Good routine maintenance of axial cylindrical roller bearing will prevent the troubles that lead to costly repairs. You can help your machine to work better and last longer by taking care of it. Cleaning and oiling, and inspecting the roller bearing housing frequently can help find little problems before they develop into big ones. You should also follow the manufacturer’s directions to prevent and maintain it for optimal performance.

1.2.Roller bearing housing structure The roller bearing housing consists of the following two main parts, the housing and the bearing. These components work together to help the machine’s shaft spin without too much resistance. The housing keeps the bearing in place to reduce vibration and support the weight of the shaft. The bearings allow the shaft to rotate without much friction. Maintaining the bearings in alignment with plenty of oil is critical to the performance of the roller bearing housing.

There are a lot advantages of roller bearing housing in factory. Designed to lift heavy, to move fast, and to last - PRECOR. Roller bearings are also knew for their long life advantages, and therefore is ideally for machines. What’s more, roller bearing housing requires less maintenance than other bearings, meaning you spend less time and money on maintenance.

When selecting a roller bearing housing for your machine, consider the load that it will support, the rate that it will move and the environment where it will operate. There are various styles of roller bearings, including cylindrical, spherical, and tapered, and all are used in varying applications. By talking to an experienced supplier such as Fo Bearings, you can ensure that you order the best roller bearing housing for your machine on the basis of what you require.

Common issues with roller bearing housing is misalignment, contamination, and too little oil. Misalignment can lead to the bearings wearing out prematurely. The bearings, too, can be damaged if dirty and clogged. Too little oil may lead to overheating and friction, which can damage the bearings. Regular maintenance, such as cleaning, oiling, and inspecting the roller bearing housing, can prevent these issues, and keep your machine’s lift running properly.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.