Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

Cylindrical thrust bearings are critical components in machines that enable them to function smoothly. These are bearings, tiny wheels that make it easier for parts to move in a machine. Without it, machines would not function as they should. In this class you will learn more about cylindrical thrust bearings and the jobs they are used in.

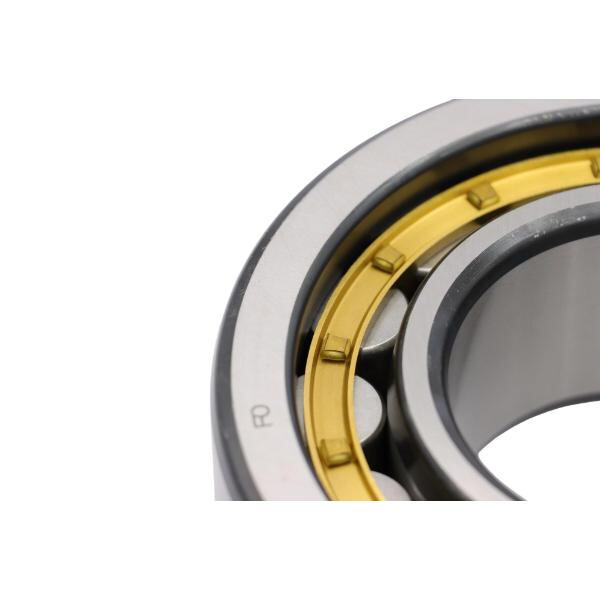

Cylindrical thrust bearing: This type of bearing is shaped as a cylinder to meet high radial load demand. They provide support for huge loads and bearings to guide the movement of machinery in one direction. These bearings can be found in engines, gearboxes and turbines. They help to minimize friction and, therefore, cause the machine to run more effectively.

Cylindrical thrust bearings are not sophisticated, yet they are causes of great consequence in machinery. They also have an inner ring and an outer ring. The inner ring is attached to the part of the machine that rotates, and the outer ring remains stationary. Between these two rings are small cylinders, called rollers, which further spread the load. This allows the bearing to support high loads and let in one direction.

Cylindrical Thrust Bearing There are a lot of reasons why you may want to use these thrust bearings for a project. These bearings can bear heavy loads and function at high speeds, so they are excellent for heavy machinery. They’re long lasting and require little care. By using such bearings, businesses can render their machines to work better as well as save money.

There is many types of the joint cross bearings for the various roles. The most popular types among rolling element thrust bearings are single direction thrust bearing and double direction thrust bearing. Single direction thrust bearings are for machines that only use one direction, while double direction thrust bearings support shafts moving in both directions. Spherical roller thrust bearings deal with heavy workloads when the weight that must be moved isn't evenly distributed.

Like all bearings, it is important to install, and maintain, cylindrical thrust bearings properly to ensure they are performing optimally. When installing, keep the bearing housing clean and apply the proper lubricant. Inspect for wear or damage, replace bearing if necessary. Taking good care of your bearings, such as greasing them and listening for unusual noises, can help bearings last longer and avoid problems.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.