Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

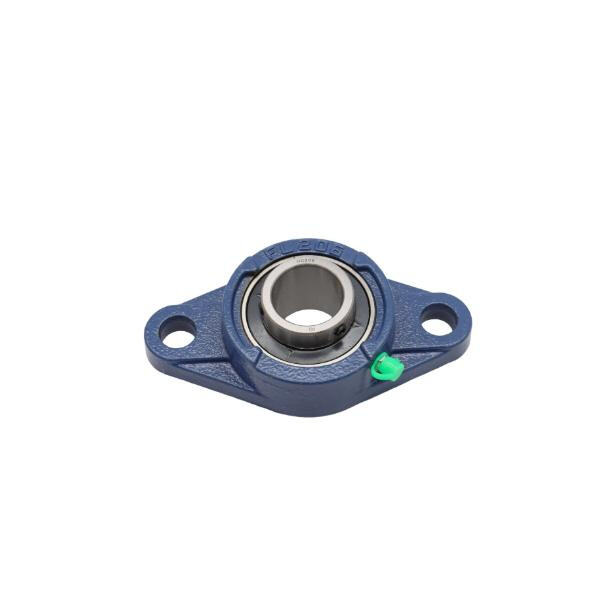

Double Bearing Housing: It’s Fun To Watch. Hopefully, that joint cross bearing as a snug little home for two tiny balls that make machines happy. These tiny balls are known as bearings, and they need a clean, secure home in order to do their job well. This is where a double bearing housing would come in!

Double bearing housing has a number of advantages in machines such as toy cars or bicycles. The first is to preserve the bearings inside. As a helmet protects your head while riding a bike, so to does a axial cylindrical roller bearing shield the bearings from damage. This, in turn, makes the machine work better and last longer without the sorts of problems associated with those previous machines.

To ensure that a bearing housing double bearing performs well, it must be well maintained. That means cleaning and oiling it. Caring for a double bearing housing Just as you wash your toys clean, a double bearing housing needs some good care as well. And, when you do the machine will be able to function without any problems.

The double bearing housing was designed separately for several machines. Some are big and strong, ideal for heavy machines such as construction tools. Others are smaller, for use with lighter devices, such as printers or fans. And everyone has its special features that make it good for some jobs, not for others. And it’s vital to choose the appropriate design for what the machine needs.

The selection of double bearing housing is very important. The way you choose to wear certain clothes for different activities, you determine the outfit the same way you determine the double bearing housing for machines. You want strong housing to hold the bearings inside and you want the housing to last a long time. With the correct double bearing housing, you can assist your machine in running at its best.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.