Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

What do I need to know about Industrial Bearings? They make for machines that move easily and well. In this article, we are going to discuss: What joint cross bearing are How industrial bearings improve machines The types of industrial bearings What applications they serve The latest technology that is used The factors to consider while maintaining these bearings to make them last longer

Industrial bearings are really small, but they are very big when it comes to ensuring that these machines work just right. Machines that don’t have bearings wouldn’t work very well either slow or smooth. Bearings, by reducing friction, help parts that are part of a machine to spin or move under control.

And then there’s industry: Industrial bearings allow machines to work better and faster. They make machines run more efficiently by cutting down on friction. This is time-saving, work-saving for machines. Machines can achieve their best with fitted bearings.

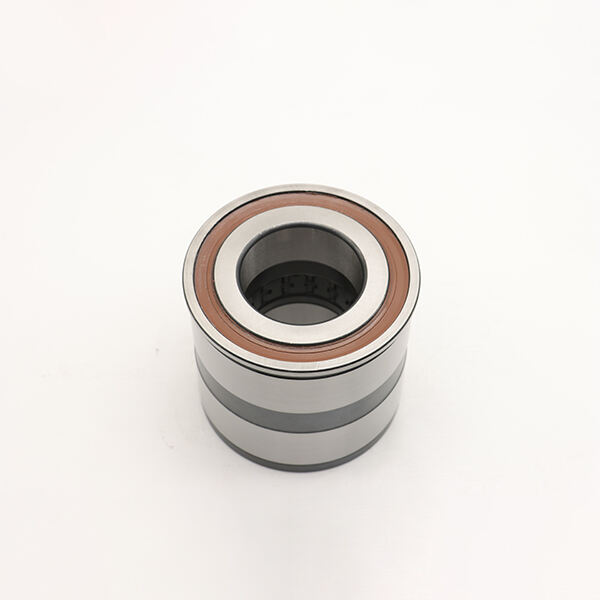

There are many different types of axial cylindrical roller bearing, and each has a special role. Some of the most common types of these bearings include ball bearings, roller bearings, and thrust bearings. Ball bearings are found in items that roll, like skateboards, roller skates and bicycles. Roller bearings are used in conveyor belt rolling wheels. Thrust bearings are commonly used in heavy machinery, such as cranes and construction equipment.

The science behind industrial bearings is also fascinating. They are constructed out of steel, ceramic or plastic. Bearings are engineered to accommodate high speeds, heavy loads, and extremes of temperature. The ball, or roller, inside a bearing is coated with the lubricant that kills friction, so it can glide along smoothly.

If you want your industrial bearings to last longer, you have to take care of them. Without regular washing and lubrication, that’ll wear out over time. That means they last longer and break down less easily. It is also a good idea to look for any physical signs of damage or overheating. Conducting bearing replacements as necessary can be good for keeping machines running smoothly.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.