Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

Plain bearings are essential machine parts that keep things moving at speed. They may not be glamorous, but these workhorses help keep machines running smoothly. Today we are going to learn more about joint cross bearings, the different types of plain bearings, the use of plain bearings, how to maintain it, and what to do if it is not working properly.

Plain bearings are modest components that cut down on the friction between moving parts within machines. They are generally made of metal or plastic, and are found in a wide variety of machines, from cars to water pumps. Plain bearings are what keep these machines running by sliding the parts with little surface resistance. Machines would wear out sooner and not run as well without plain bearings.

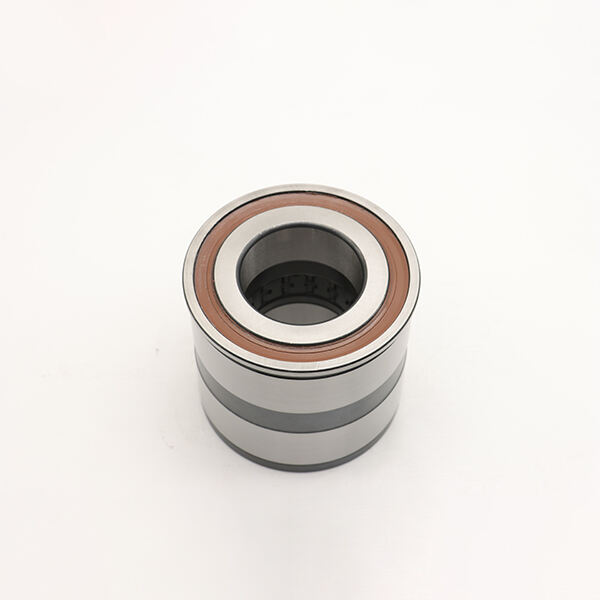

Plain bearings are of various forms used in a wide range of machines. Common types are sleeve bearings, journal bearings and thrust bearings. Sleeve bearings are just plain tubes, that fit around a shaft, and are used to minimize friction. RoundJournal bearings have a round shaft that fits into a hole in the bearing to provide a smooth bearing surface. Thrust bearings are employed to support load from a machine like a crane, while reciprocating motion is occurring.

The use of journal bearings in machines has several advantages. They are simple and affordable to produce, which helps maintain the cost of machines at a minimum. Plain bearings are also less high-maintenance than other varieties, making them good for machines that need to run for extended periods without a break. What’s more, axial cylindrical roller bearings are able to tolerate heavy loads and high speeds, which means they can be applied widely to machines.

Plain bearings must be kept well-lubricated to work well. That means oiling or greasing the bearing to minimize friction and wear. You should also wash the bearing to be free of foreign objects such as dust and dirt, because these impurities will cause the bearing to wear and to run on a loose line. And if a plain bearing begins to sound noisy or wobbles, it may need to be replaced or repaired to ensure the machine operates smoothly.

If a plain bearing is not functioning properly, there are a couple of things to examine. First off, ensure the bearing is clean and lubricated. If it still doesn’t fit, it may be worn or damaged and should be replaced. If it still can not work, please contacted a professional technician for help.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.