Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

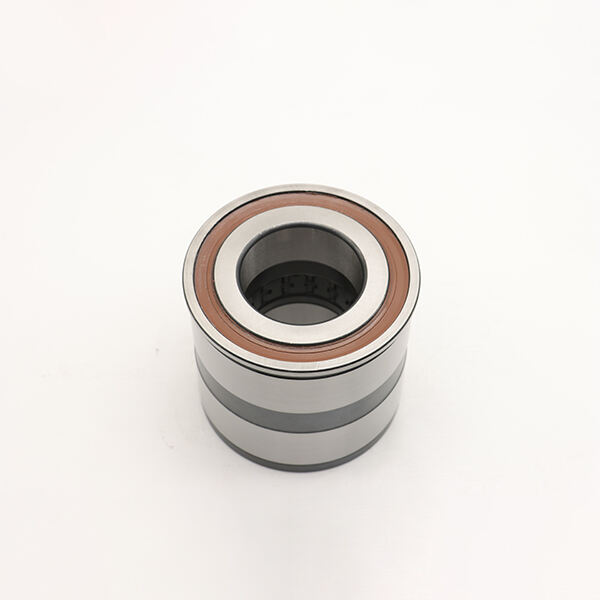

Ever wondered how your car’s clutch works? So, what's an important component of it like - the release bearing. The release bearing (a k a throw-out bearing) is essential for that smooth clutch action.

It allows the pressure plate to move away from the flywheel when you step on your car's clutch pedal. This leaves a gap for the engine and the transmission so there doesn’t need to be a problem when you switch gears. Once you release the clutch pedal, the release bearing assists in pressing the pressure plate back to the flywheel. This results in power being transmitted from the engine to the wheels.

Like any other part in your car, the release bearing requires maintenance to function properly. Regular maintenance checks and lubrication can help it last longer and prevent the incursion of issues like grinding noises or difficulty changing gears. If you neglect it, the release bearing can wear and fail, making it an expensive repair.

But some signs that you might need to change the bearing also are discussed here if you see any of these signs you need to change your release bearing:

Selecting the Correct Release Bearing for Your Vehicle When selecting a release bearing for your vehicle, it is crucial to select the right one for your clutch kit. Consider the kind of clutch (mechanical or hydraulic), the size of the release bearing, and whether it is compatible with the make and model of your car. Speaking with a professional mechanic, or looking in your car’s manual, will help you take a look at what size bearing you’ll need to install.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.