Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

Sealed bearings are a part of many of the machines that humans use every day. It helps facilitate the motion of moving parts in a machine. Sealed bearings are used by companies like Fo Bearings to ensure that your machines last longer and perform better. In this article, we are going to talk about the great things that joint cross bearing do, how they keep the machines in clean condition, how many models there are available today as well as taking care and some good reasons to invest for certain type of fast and/or tough conditions.

Machines have a lot of good things about sealed bearings. One primary advantage is that they keep the insides safe from dirt, dust, and other harmful stuffs. This prevents the machine from getting gummed up and can extend its life. Sealed bearings also require less maintenance than open bearings, which can save you time and money. They are also less noisy and operate more smoothly, so they make the machines function better.

Keeping the machines clean is critical. Machines operate in dirty, particle-filled environments in some instances. Sealed bearings contribute by providing a barrier that shelters the interior components of the equipment. That barrier will keep out dirt, dust and water, which can be damaging to the machine. Companies can gain an edge by using axial cylindrical roller bearing to extend the life of their machines and sidestep the cost of repairs.

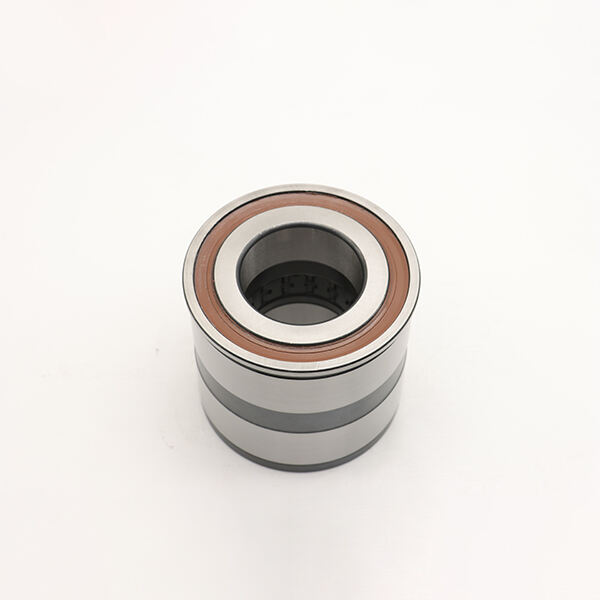

The sealed bearings come in many types of special features. Some of those type are: Rubber sealed bearings, Metal shielded bearings, Ceramic shielded bearings. Rubber-sealed bearings are excellent for keeping out water and dirt. Metal sealed bearings are tough and can withstand high heat. Ceramic-sealed bearings are lightweight and do not rust, so they’re suited for harsh environments.

Sealed bearings, however, have to be looked after to work effectively. Cleaning and lubrication can get some of them running. Companies like Fo Bearings advise you to follow the care and checks instructions to forefend problems. Taking care of sealed bearings can also allow companies to make their machines work better and not break down.

Protected bearing is great for riding fast or hard. They can withstand heat, water and heavy loads. The seals of the bearings on these pedals prevent grime from getting in and will have you sorted for riding in dirty places. And companies can make their machines more reliable and save money in the long run by using sealed bearings.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.