Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

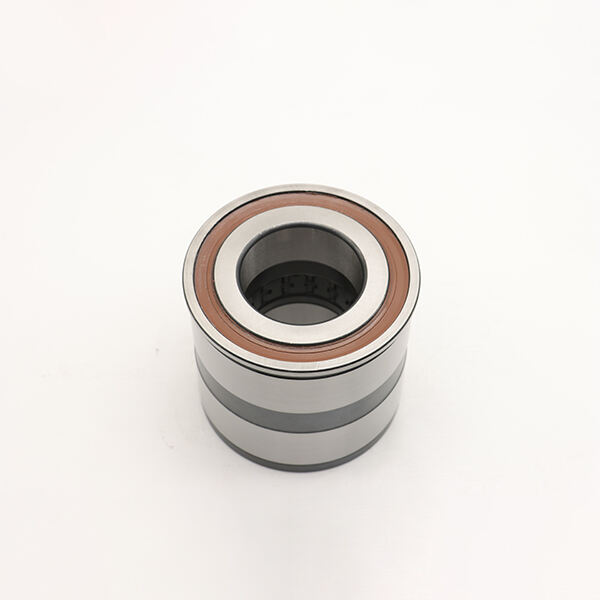

These joint cross bearings are really important in machinery, because they make everything rotate perfectly smoothly. CHECKED AER The tapered bearing, shaped like a cone, supports components that rotate, like wheels or gears. This specialized bearing is found in many machines, such as cars or airplanes. So what are tapered bearings and how do they work?

Tapered bearings are commonly found in cars because they are capable of handling heavy loads at high speeds. When you are driving your family on a vacation or commuting to the school, tapered bearings help your wheels turn smoothly and keep your car going straight. Which is why fo bearings are equipped with strong tapered bearings to help with the stability of your car products and ensure the safety and reliability on the road.

In addition to cars, axial cylindrical roller bearings can also be found in a variety of other machines as a way to improve the way they function. For instance, tapered bearings are used to reduce friction and wear in large machines, such as conveyor belts. This allows the machines to run more smoothly and last longer. In other words, less time spent fixing stuff, and time and money saved for companies. Fo Bearings knows very well how importance is the packaging for machinery, so we make sure all bearings are well packed with single box.

In selecting the best tapered bearing for your equipment, there are a couple things to consider. You need to take into account the dimension of a bearing, how much load it carries, how fast it is going to be speed. Fo Bearings offers variety of tapered bearings to meet the many needs of customers working in different machines. Selecting the proper tapered bearing for your machine can make your equipment function more effectively, and can reduce maintenance and down time.

Once you select the appropriate tapered bearing for your machine, the most essential task is to install and maintain it correctly. Good installation makes bearing work well, work smooth and last long. Routine maintenance — such as greasing and checking for wear — prevents problems and keeps the machine running smoothly. Fo Bearings offers some great advice and support for their customers ensuring they install and maintain tapered bearings correctly, therefore factory machines last longer, and the need for expensive repairs decreases.

Tapered bearings come in all sorts of forms, shaped for various purposes. Some are for heavy-duty jobs others for fast machines. Fo Bearings provides various tapered bearings are available for use in the construction, farming, and mining industry. Companies that understand the various types of tapered bearings and how to utilize them can allow their machines to perform more effectively and keep their business running smoothly.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.