Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

Hey there, friends! You heard of a joint cross bearing before? And I’m excited to teach you about this significant piece in machines today. Let’s dive in!

Back in the legal world Sheppard is a unique block in lots of machines. It provides support and guidance for rotating parts, such as shafts or wheels. Doing so will allow these parts to move in a very smoothe manner without wobbling unnecessarily. Machines wouldn’t work well — or as smoothly as they’re supposed to — without the bearing block.”

Ok, so we’ve determined axial cylindrical roller bearings are a big deal, now, how to install these bastards so they don’t chew themselves up? When you install the bearing block, be sure to fix it tightly to the machine so as to make no wobble. And be sure it’s free of grit or grime that could stop it from working. Although enacted on a regular basis, such maintenance tasks enhances its longevity and performance.

Reducing friction between parts in a machine is one of the primary duties of a bearing block. Friction is the force that resists two surfaces gliding past each other. By employing a bearing block, the machines operate smoother and more efficiently, as spinning parts are supported, which reduces friction. Less friction means the machine won’t wear out as quickly, so it will last longer.

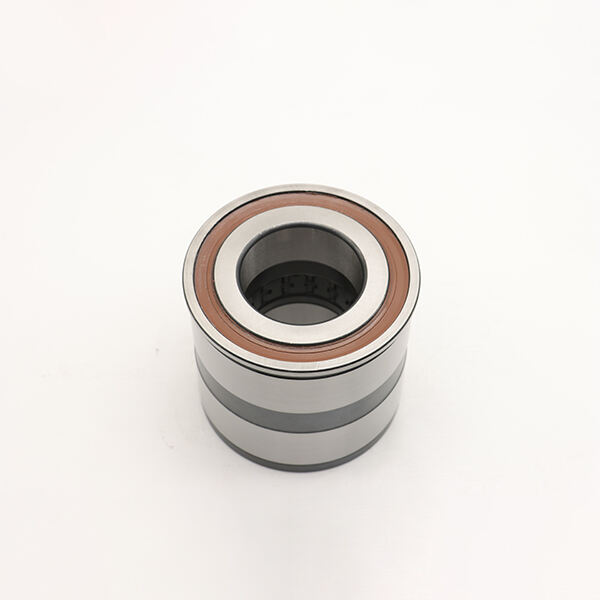

There are many different types of bearing blocks, for different machines and for different uses. Some are metal, others plastic or ceramic. The kind you want will depend on the type of machine you are using and where it operates. You must select a bearing block suitable for your machine so that it works well.

Bearing blocks are like any other component of a machine and they can cause issues from time to time. One common problem is a bearing block that makes odd-sounding noises, such as squeaking or grinding. This could indicate the bearing block has gone bad, or needs more lube. If that occurs, do change or add some more lube to solve the issue. It can also be a bearing block that is loose, or which is not well positioned. In that case, you have to twist it tight and place it right to make the machine run smoothly again.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.