Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

A joint cross bearing is a critical part of a marine propeller system. It enables the engine to operate smoothly and sailing to be safe and enjoyable. In the following article, we are going to explain reasons as to why gimbal bearings are important, also know how to maintain the gimbal bearings, how to change the gimbal bearings, and how it helps you to reduce the vibrations on the boat, types of the gimbal bearings, and swims down the cameo tips on how to solve the common issues.

Gimbal bearings are critical components which hold the drive shaft of a boat’s engine. They assist the engine to run smoothly, thus reducing the friction and wearing on the engine’s pieces. If a gimbal bearing does not function properly, it can cause the engine to shake excessively, leading potential damage and safety issues.

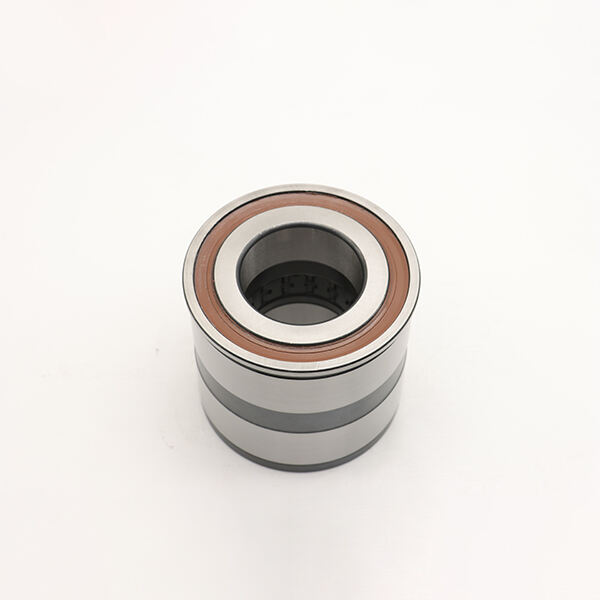

GIMBAL BEARING MAINTENANCE To protect your axial cylindrical roller bearing over the years, it is important to ensure proper care. Try to move the bearings to see if there is any sign of damage, such as rust or sloppiness. Adding some grease to the bearing now and then can make it operate smoothly and wearless. If it must be replaced, it’s good to get help from a professional so it can be put in properly.

Gimbal bearing minimize the shaking in the outdrive and the prolerller by keeping them in place. The bearing eases the task of supproting the drive shaft, and at the same time shares the load, reducing the burden on the engine parts. This extends the engine’s life and provides a smoother ride for everyone.

There are various types of gimbal bearings, all designed to fit certain boats and engine powers. To ensure it works well — and lasts — it’s important to select the right one for your boat. As you select a gimbal bearing for your boat, you should consider the size, material, and how nicely it fits with your boat engine. But asking a professional or consulting the manufacturer’s guide can help you make a good decision.

If you begin having problems with the bearing of your gimbal, such as loud noises or shaking, you will need to address them in a timely manner to prevent further damage. Typical issues are misalignment, lack of lubrication, and wear. Through regular inspection, and maintenance of your gimbal bearing you can discover issues before they build up into expensive repairs.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.