Room 1709, Changan Square Office Building, Changan District, Shijiazhuang City, Hebei Province

+86 18931989553

[email protected]

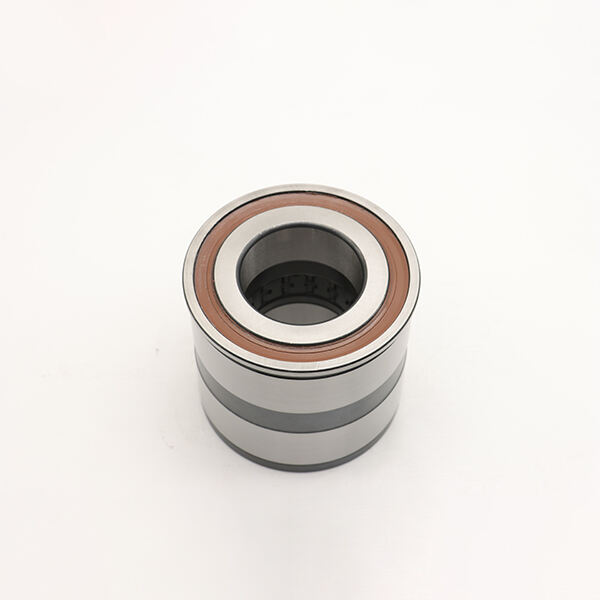

Did you ever wonder how it is that machines move so effortlessly? This is precisely where joint cross bearings are useful! The main use of bearing rods is as a component of machineries that aiming to minimise friction, which easing the movement of a certain parts. Just as a wheel keeps a bicycle rolling along smoothly, bearing rods help machines operate well.

Think about biking with squeaky wheels; it wouldn’t be enjoyable, would it? Bearing rods, of course, are no exception. It is like anything else, it’s important for them to be lubricated so they work well and can be used for as long as possible. Lubrication is used to prevent damage caused by friction. That said, just don't forget to lube any of your profile rods!

These axial cylindrical roller bearings require care, just as a car requires care to keep running well.” But how do you know when your bearing rods are getting old? Look for signs such as unusual noises, shaking or difficulty moving. If you notice any of these signs, it may be time to replace your bearing rods to prevent further damage.

Now that you understand the importance of lubrication, and how to identify fried bearing rods, we should talk about how to extend the life of bearing rods. There are a few ways you can help ensure this doesn’t happen, one is by regularly inspecting and maintaining your bearing rods. Just ensure they’re clean and lubricated with the right stuff. Also, don’t overload your machines, or use them in harsh conditions that would strain the bearing rods.

When you’re selecting the perfect bearing rod for your machine, you may want to consider factors such as how much weight your machine can take, the speed your machine needs to reach, and what type of working conditions your machine will be used in (under dirt, heat, or the elements). Speak with a professional or research the decision on your own so you know what to expect. Just think, the correct bearing rods can make your machines run smoother and last a lot longer.

With over 20 years of dedicated experience in bearing production, we specialize in developing and supplying high-precision solutions including wheel bearings, hub bearings, and clutch release bearings, ensuring reliable performance across diverse industrial applications.

We offer comprehensive OEM and ODM services, tailoring bearings in various styles, sizes, and specifications to meet unique requirements in automotive, machinery, and energy sectors—delivering both superior quality and competitive pricing.

Backed by a multinational presence through subsidiaries in Iran, Canada, Malaysia, and the UK, we provide responsive 24/7 localized support, ensuring seamless technical assistance and smooth cross-border collaboration for clients in over 60 countries.

Every bearing is precision-manufactured through forging, heat treatment, and machining, supported by a rigorous quality management system that includes automated inspection, material testing, and noise/vibration analysis to guarantee durability and performance.